This new machine has been designed with health and safety approval for fast and consistent polyester welding and encapsulation.

Not using jaws means you are not restricted by the jaw width, and can continually weld very wide sheets. This style of operation allows much more room to work with the material you are sealing.

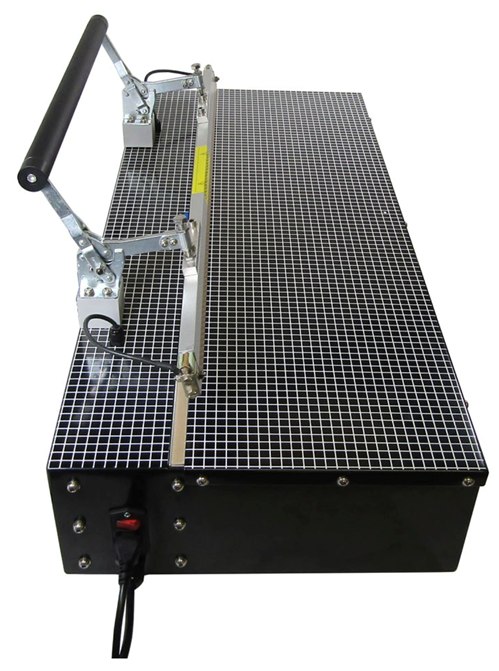

The Crossweld™ is designed especially to suit the welding of polyester film, which requires a flat support surface both sides of the weld. The sealing of polyester film requires machines that have been manufactured for the precise welding of the very narrow band melt point of polyester film, if it’s too high it will melt through the film, too low and it will not seal. The welding element must be fitted to the top moving jaw, not on the base/bottom as with bag sealers, this is essential for lining up the weld and sealing polyester to board.

The heat compensating device uses the latest electronics to ensure consistent welds every time.

The Crossweld™ can be used for sealing various thicknesses of polyester film and other materials to make pockets, sleeves and bags.

The working alignment grid squares can be replaced when worn. Replacement heating elements and PTFE material are easily installed. The PTFE cloth protecting the welding element is simply replaced by winding new material into place from the roll attached to the machine, a real advantage for quality welds.

Make enclosures, pockets, sleeves and bags with many materials, Polyester bonded to paper or board, Reemay, Hollytex, Tyvek, PEL Softwrap, Bubble film, Marvel Seal

Size : Length 910 mm, width 400 mm , depth 170 mm

Complete with instructions, spare element and PTFE cloth

Each machine is shipped in a wooden crate arriving ready for use

| Code | Description |

| A806-8000 | Crossweld Polyester Film Sealing Machine |

| A806-7002 | Spare PTFE Cloth 700 x 600 mm |